Have you ever had the eyelet strip or have the button become difficult to turn on your bow? I freaked the first time I experienced this as a student, fearing that something might be catastrophically broken. Almost in tears, it came as comforting news that the screw and eyelet is designed to have a service life and meant to be replaced over time.

Though there are many factors of why a bow may not tighten or loosen, including the rehair; the screw and eyelet is an integral part to the bow functioning properly. I wanted share some insight about these elements of a bow and hopefully give you a better understanding of the simple machines involved.

Eyelet

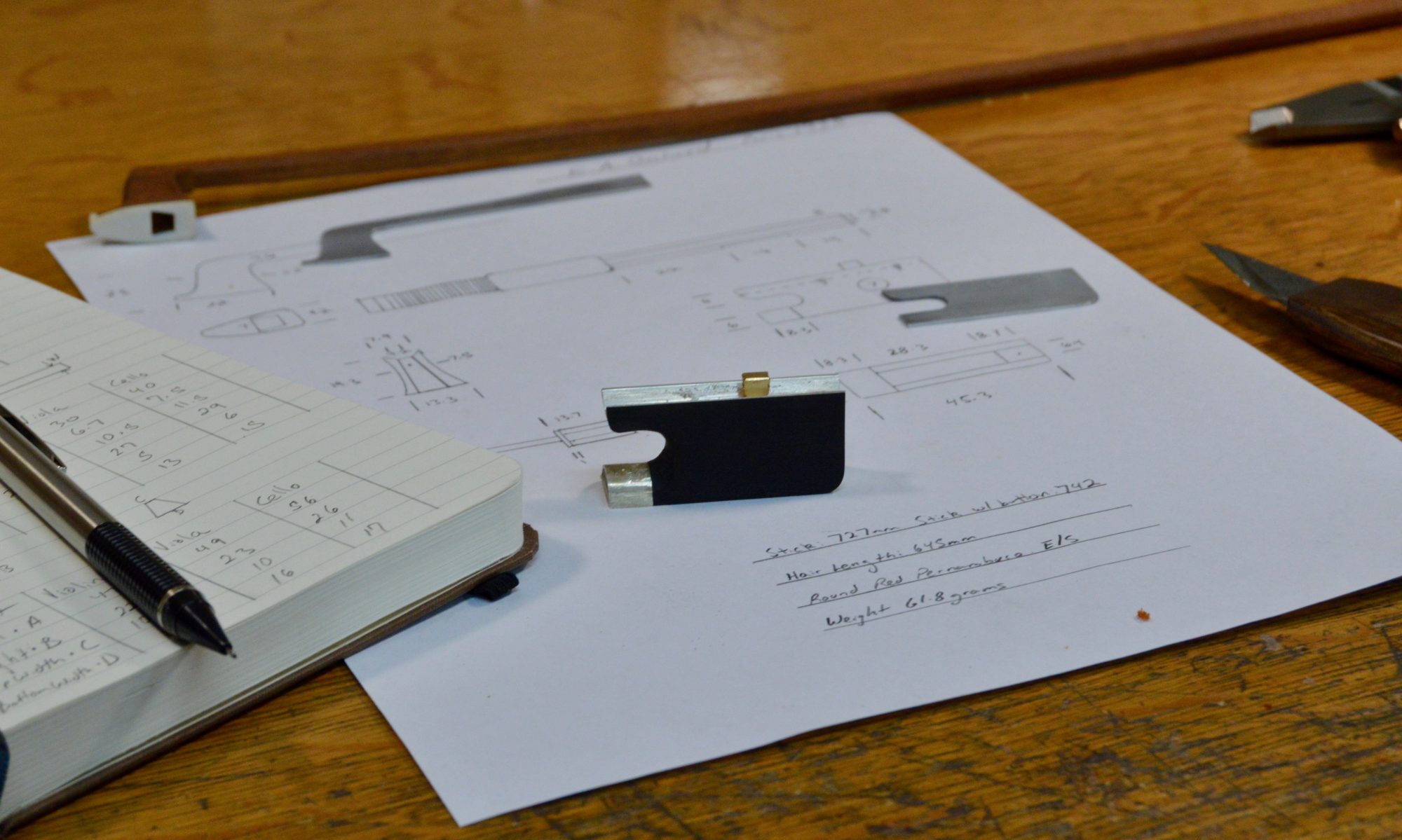

The eyelet, typically made of brass or bronze, in the frog interacts with the screw and button so that the frog can travel forward and backward along the stick. The eyelet is screwed into the frog and can be set at range of heights having an effect on how tight the frog mates the stick. It is important that the frog not be too loose on the stick as the frog can easily be damaged if there is any side-to-side play. Conversely if the frog is too tight, you can cause excess strain on the screw and eyelet resulting in premature failure of the parts. It’s better to be a bit snug and on a brand new bow it is not uncommon for the frog to fit a little snug. Everything will usually wear in nicely and function great for years to come.

Over time the threads inside the eyelet become worn and the screw won’t engage the eyelet. Replacing an eyelet is an inexpensive and standard repair for bow makers. Eyelets are also purposefully made of a softer material as to protect the stick from damage. If the hair is stretched out and the frog is allowed to travel back far enough, the eyelet can wedge up against the back of the mortice and crack the stick. The hope is that the threads fail before the wood does. Additionally, worn screw holes and misaligned screws can contribute to untimely failure as well.

Replacement of an eyelet is not a simple drop-in kind of service, it requires careful matching of the threads to the screw along with setting it at the correct height. The eyelet should also be shaped to have clearance inside the mortice on all sides and the edges softened or chamfered as to not damage the interior of the mortice.

Screw

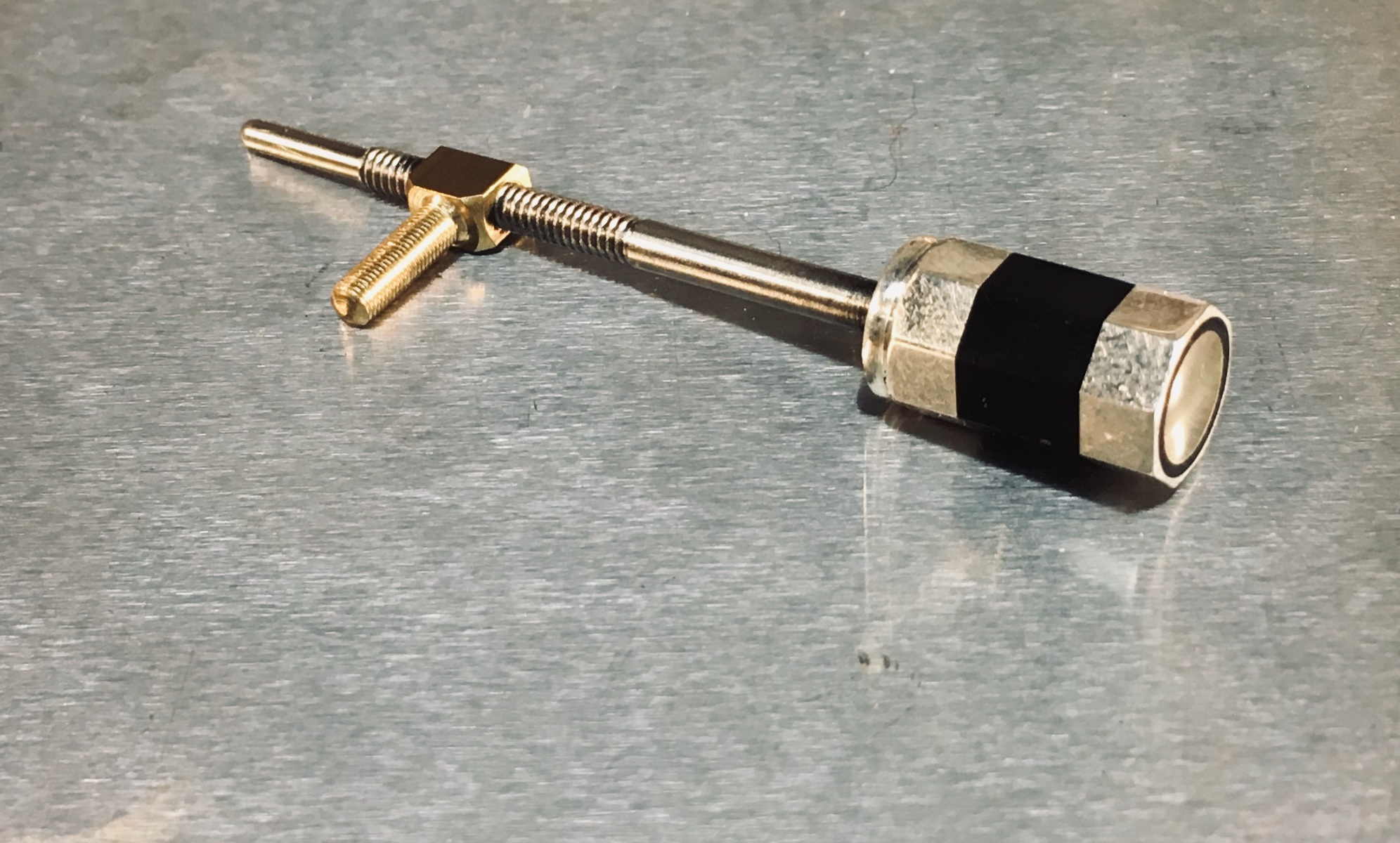

The screw attached to the button can be made of different materials including steel, stainless steel and titanium. They can have different pitches and TPI including: 5-32, 5-36, and 5-40 and 3 mm x 0.5 mm and 3 mm x 0.6 mm (for us geeks out there). Where the threads of the screw line up in the mortice is very important. If the screw sits in too deep the threads can start to bore into the front hole. This can cause an array of issues too many to list exhaustively but could include cracking the stick, introducing play into the fit of the frog, and separation of the button and screw.

While the screw has a longer service life then the eyelet. The threads can become worn or damaged and needs to be replaced as well. Extracting a broken or damaged screw from a button can be tricky if one isn’t familiar with the particular school of making. For example, some schools of work and individual makers will thread the screw into the button as well. Once again, careful attention to the dimensions and threads are important here along with how deep the screw fits into the button and where the threads line up in the stick.

Maintenance

When your bow is brought to a bow maker for rehair, they will clean the screw and eyelet along with the liner on the bottom of the frog. They will make any necessary adjustments to the eyelet and lubricate all moving parts. Bow makers use smooth parallel jaw pliers to adjust the eyelet. Never adjust the eyelet with the screw, I’ve seen so many liners on nice bows damaged this way. If you feel that your eyelet needs adjustment, bow makers can quickly and accurately make proper adjustments.

Between rehairs, you can keep the screw and eyelet lubricated to ensure smooth operation and extend the service life of the parts. A commercially available bow lubricant is available from award winning bow maker, Rodney Mohr.

2 Replies to “Screw and Eyelet”